A detailed look at why the tech firms like Apple and Google are looking west – manufacturing in the USA instead of China.

Designed by Apple in California. Assembled in China.

This is one ubiquitous line present across all the Apple devices. Same is the case for other electronic gadgets too.

Of late, tech firms like Google, Apple, GE have been announcing their manufacturing and assembling units in USA. Motorola ran a newspaper advertisement of its Moto X phone by touting its USA origins.

Why China till now ?

Outsourcing the manufacturing process to the east (read China) has been a trend across all industries in the USA. This is obviously due to the lower costs in Asian countries compared to what they are in America.

Who/What all are moving to America ?

| Company | Product | Place |

| Google – Motorola | Moto X | Fort Worth, Texas (once used for Nokia phones) |

| Apple | Mac Pro | In the USA. (Rumoured to be in Texas) |

| Lenovo | ThinkPad | North Carolina, USA |

Why the sudden interest in USA ?

There are obviously economic, strategic and marketing reasons behind the new ‘look west’ policy being adopted. Here are few of the reasons:

- China losing its price advantage

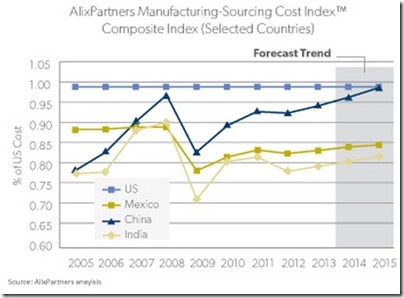

A survey by AlixPartners provides an analysis of the cost of manufacturing in east Asian countries plus shipping costs to the US compared to the cost of manufacturing in the US.

The above comparison chart clearly indicates that China has had price advantage over the USA for quite some time. However, it is predicted that the costs associated with assembling in China and shipping to the US would equal the costs of manufacturing in USA by 2015.

National Bureau of Statistics in China indicates that manufacturing wages have increased by 71 percent since 2008. In addition to the rising wages, the transport costs involved in shipping the manufactured items across half the world (from China to USA) are on the rise.

- Time constraint in shipping from China to USA

There are other strategic constraints involved in shipping every gadget from China to USA. Technology can as well be considered a perishable item. Delay in getting items to the USA can possibly affect the success of a gadget or a technology especially in the fast changing technology era.

- Tackling the customer perception

Yet another important reason behind this strategy is the identification of new brand positioning by striking a chord among the US customer base.

A survey by BCG has shown that more than 80% of the consumers in USA prefer “Made in USA” brands to those “made in China” and are also ready to spend extra for these products. This perception can be attributed to the low-quality factor associated to Made in China goods.

When the PC maker – Lenovo - moved its customer support center for web and telesales from Bangalore(India) to North Carolina(USA) it lead to a 25 percent increase in satisfaction ratings.

“Made in USA” tag - not sufficient

This Made in USA label itself is not sufficient in having a sustained customer support. Do remember the rise of Japanese automobile manufacturers over USA automobiles. It is always quality/customer satisfaction first in this highly competitive tech space.

In fact, the Apple campaign about its “Designed by Apple in California” label has not been received well by viewers according to a survey explained in detail on Apple Insider. Here below is the video advertisement :

Prediction for the future

Moving out of China completely is definitely not an apt solution especially when there is an ever growing customer base in developing countries around China (like India).

Customers in such countries are price conscious and continuing the current manufacturing in Asian countries makes sense for this target segment. This strategy could as well help in mass customization of products intended for specific markets. For example – imagine a low cost iPhone for customers in India being sourced from China and a premium variant being manufactured in the USA for the customers around America.

This kind of strategy might also help in addressing the operational issues in case of shortage of supply in any of the manufacturing units.

Other articles taking this further:

Recommended Reading

No comments:

Post a Comment